Featured Products & Services

|

Vertical Divider

What Is a Low-Profile Clamp and How To Utilize It In Your ProductionA brief history of wedge operated workholding clamps.

In the late 1970’s, Finnish inventor and entrepreneur Mr. Olli Kytölä developed a new clamping method for workholding. The simplicity of the idea is mind-blowing even today: instead of moving large machine vise jaws against each other, a small wedge-operated jaw is pressing the workpiece against fixed stoppers. The clamp has two jaws, so possibility to clamp one or two workpieces with one clamp is built-in. During last 40 years, this wedge operated workholding clamp has become famous with the name OK-VISE Low-Profile Clamp. The core application has always been in CNC milling, an in early days do-it-yourself people used to build their own workholding fixtures using OK-VISE clamps and milling the remaining parts of the milling fixture themselves.

Today the wedge operated clamp is widely used in machine shops all over the world due to its many benefits compared to normal vises. In our Fixturing Concept, the idea is to have locating components like stoppers, side guides and parallels as separate modules. These modules locate the workpiece, and clamps are used in most cases to clamp the workpiece against stoppers.

The clamping itself is very simple. When we are tightening the clamp, the wedge in the middle pushes the jaws sideways, pressing the workpiece against a fixed stopper. In addition to dedicated workholding, the low-profile clamp is often used in modular workholding systems, such as Multi-Rail RM. This approach, involving standardized modules for fixture designers and fixture builders, speeds up fixture sourcing radically, especially if a modular base rail is in use. Best-case scenario is that no machining at all is needed to build a new fixture.

Different clamp models:

When we are talking about clamping the workpiece securely and safely for machining, it is important to look at various clamp models and their strengths. The features of the machining process and the workpiece typically determine the requirements for the clamp. In most fixtures, so called force-closure is being used. This means that typically 3 sides of the workpiece have free access to milling tool, and holding force opposing the machining forces is created by friction. When dealing with high forces during machining in force-closure fixtures more friction is needed between the jaw and the workpiece. This can be achieved by selecting a larger clamp (for bigger forces) or a model with enhanced grip for better friction compared to a smooth-jaw clamp. Luckily, you can find a range of clamp options from us to securely attach even the most challenging workpieces. For better friction:

Tungsten carbide coated jaws are extremely useful when no clamping marks are allowed in the workpiece, yet high holding force is required to hold the workpiece. With tungsten carbide coating the holding force is about double compared to traditional smooth jaws. it has to be noticed that the marks that these jaws leave to the workpiece are almost invisible. Serrated jaws are used when even higher holding forces are needed. When tightened with high force the serration penetrates into the workpiece, creating high friction. For complicated shapes:

Sometimes the workpiece has a complex shape, which we need to consider when selecting the right clamp. In these cases, the clamp can have an adjustable jaw, or the jaw itself can be machined to match the shape of the workpiece. Self-adjustable model is a great option when the workpiece has irregular shapes. These clamps have a self-adjustable ball pressure screw inserted into a clamp jaw which can adjust by the shapes of the workpiece. Direction of the jaw movement:

In mostly used the jaw slides along the fixture base. These are called hold-down models, because the wedge design holds the jaw down and prevents the jaw from lifting up while clamping. The other option are pull-down models, where the jaw moves also towards the fixture base. When clamping the workpiece with this type of clamp, the workpiece is also pressed down. Another advantage is that with this clamping technology, we can achieve even higher clamping force, up to 15 kN.

One way to build a workholding fixture is form-closure, where the geometry of the layout prevents the workpieces from moving. Another and more typical application is force-closure, where the friction between the workholding clamp and stopper jaws create a holding force that prevents the workpieces from moving. In most typical application there are 2 workholding clamps and 2 stoppers, each with the same force clamping the workpiece. When this force is multiplied by friction coefficiency µ, then we can calculate the holding force, in the above mentioned example. H = 4 µ F

where F is the clamping force, and friction coefficient varies. Example values when workpiece from steel is in use. µ = 0,15 smooth jaws µ = 0,28 tungsten carbide coated jaws µ = 0,8 serrated jaws What we have learned:

All in all, using a wedge operated clamp is one of the easiest and best ways to build workholding fixtures. Its operation allows you to use it for clamping multiple workpieces simultaneously or when you need a high clamping force in limited space. For more details about our low-profile clamp, we have gathered product information in our instructions. Contact us for more details

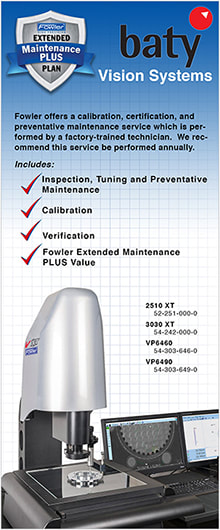

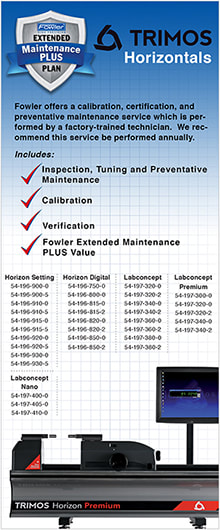

Fowler's Extended Maintenance

|

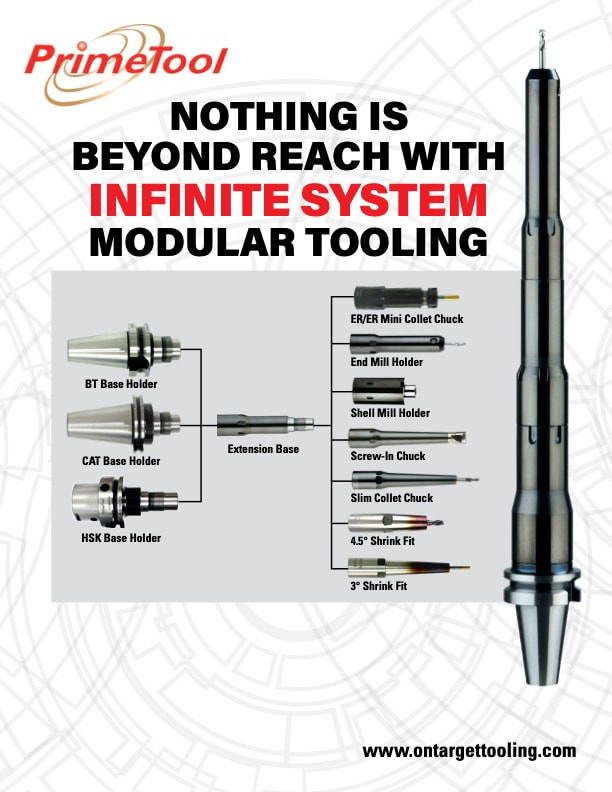

I-System Tool HolderThe Infinite Tool Holder System utilizes a patented tool holder base available in the most popular machine tapers featuring eight different “IR” coupling sizes. The base and couplings have highly accurate ground pilot diameters and threads providing excellent concentricity and rigitidy to allow limitless tool holder lengths.

The Infinite Tool Holder System provides the ultimate in customer interchangeability. Contact us for more details

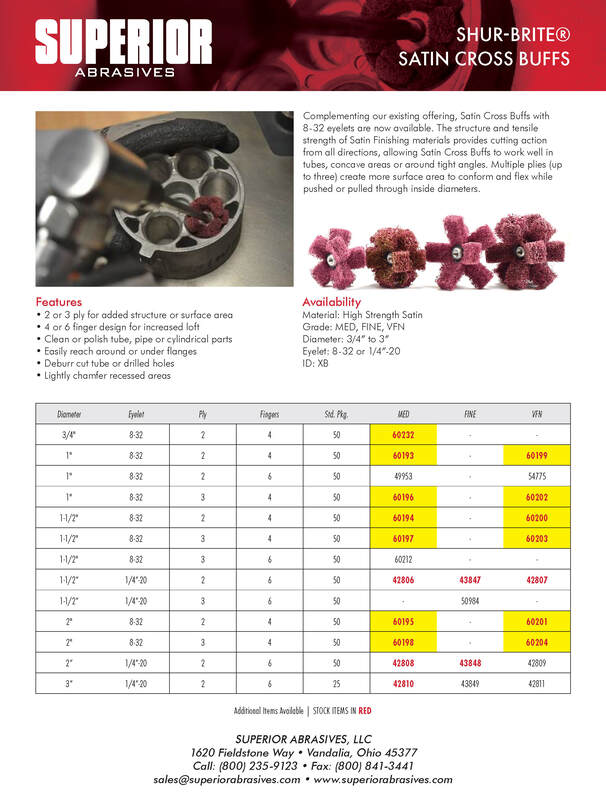

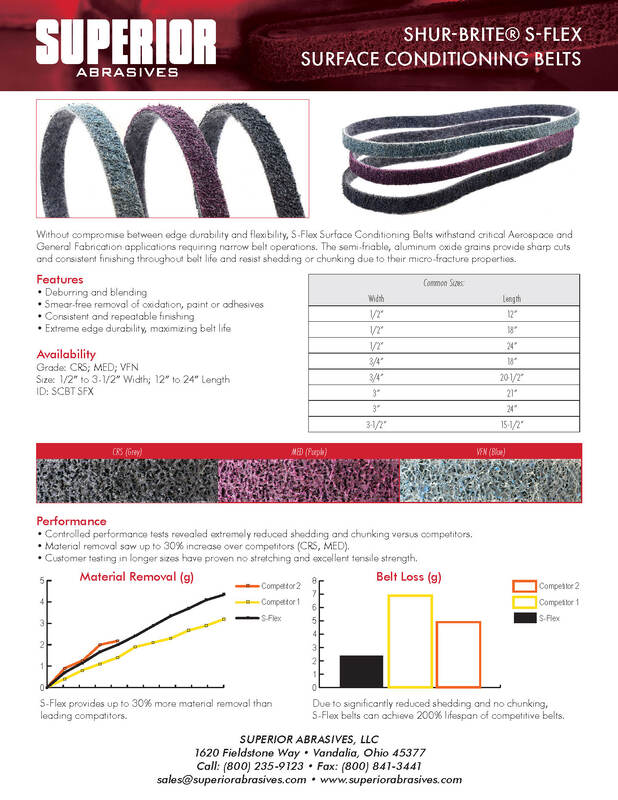

Superior Abrasives

|

|

New Products!

New Savings! Download PDF here. |

Contact us for more details!

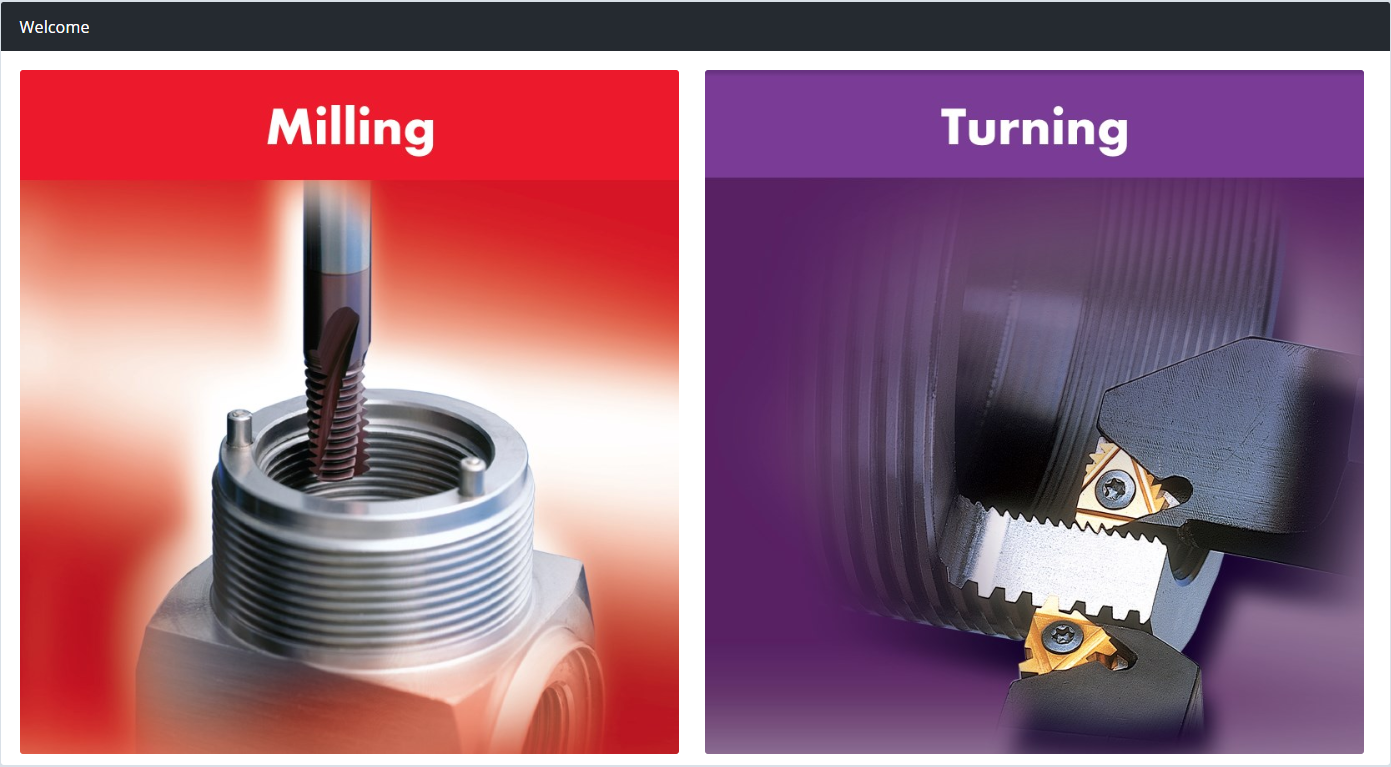

Carmex Tool Wizard

IS NOW AVAILABLE AT ON OUR WEBSITE!

- Go to our Programming Software page.

- Click on either Milling or Turning to pull up the Carmex Tool Wizard.

- Move the cursor over Milling or Turning and “start” the program.

- Tool Wizard suggests tools to be used, generates the program, gives the number of passes, and how much material is removed on each pass.

This is a great tool for our customers!

Contact us for more details!

Portable Precision - " The Next Dimension"

A revolutionary solution to a complicated problem.

Using advanced technology, software, design and electronics, the zCAT is manufactured as a compact self-contained unit that is fundamentally different than existing CMM technology, design and operation. From initial equipment acquisition through set-up, training and maintenance, the zCAT offers significant cost reductions without compromising measuring accuracy or performance.

For more information, download the zCAT brochure here: ZCAT DCC CMM

Using advanced technology, software, design and electronics, the zCAT is manufactured as a compact self-contained unit that is fundamentally different than existing CMM technology, design and operation. From initial equipment acquisition through set-up, training and maintenance, the zCAT offers significant cost reductions without compromising measuring accuracy or performance.

For more information, download the zCAT brochure here: ZCAT DCC CMM

Contact us for more details!

Purchase any Spiral Mill-Thread inserts and receive a FREE corresponding tool holder.

Since its introduction, the Spiral Mill-Thread line has become one of Carmex’s most popular products. NOW, customers have the opportunity to purchase the inserts and receive the corresponding, specially engineered tool holder FREE.

Contact us for more details!

Thread Mills for Medical Applications

Carmex introduces thread mills designed for the double- and

triple-start tapered threads used on orthopedic bone plates.

These thread mills are quoted and sold per application.

triple-start tapered threads used on orthopedic bone plates.

These thread mills are quoted and sold per application.

Contact us for more details!

Indexable Threading Specials

With our expertise in threading tools, we welcome to opportunity to help you with your special threading application.

Contact us for more details!